TA-Debugger

Changelog:

Date: April 30, 2025 Version: 20250430

Fixed the bug of brake locking or unlocking

📌

After this version is updated, it can be used directly without restoring factory settings

Date: March 28, 2025 Version: 20250325

Update firmware and debug software:

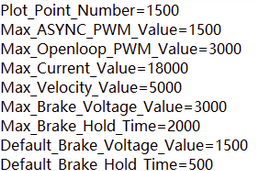

- The input value limits of each motion control mode can be set in the ini file. And some interactive bugs have been solved

- About the brake:

- Added brake automatic opening(closing) voltage setting to the parameter preset page of the debugging software

- The program internally processes the brake, and the original PWM duty cycle method is updated to recalculate the PWM corresponding to the accurate voltage value according to the current power supply voltage, and then apply it to the brake. This prevents the brake from being too impacted by a high voltage power supply such as 50V, causing rebound.

- On the motion control page, the brake input PWM is changed to a voltage with a unit of 0.01V, and the value range remains roughly the same. For example, if you enter 2000, the original meaning is 2000 PWM, 2000/4000=50%, which is a 50% duty cycle. The new meaning is 20.00V, which is 20V. For another example, if you enter 1500, it is 15V

- About temperature:

- On the protection setting page of the debugging software, relax the maximum value of over-temperature protection to 180

- The temperature display range of the motion control page of the debugging software is adjusted from -128~+127℃ to -75~+180℃. This change is made for the convenience of extreme testing.

- When the motor NTC is not connected, that is, when the NTC resistor is infinite, the temperature is displayed as around -65℃. This is a bug, this should have been the case, but the conversion process had an unexpected result that caused the negative temperature to become 0. This update fixes this bug.

- Change the description of the MIT parameter in the “pid parameter setting” of the debugging software

📌

Note:

- If the motor is already on the arm and it is not convenient to recalibrate it, you need to manually go to the parameter preset page of the debugging software and set the voltage value of the automatic opening(closing) of the brake to 1500, so that it can work normally later.

- For the free actuator, simply restore the factory settings and recalibrate it.

Date: March 25, 2025 Version: 20250323

Update debugging software:

- Some sorting and supplementation of the debugging software motion control page, adding English comparison

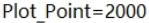

- Waveform drawing, configurable number of points for refreshing the page

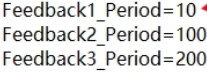

- CAN Feedback 3 cycle parameters, configurable return time

Date: March 19, 2025 Version: 20250319

- The MIT mode operation cycle is changed from 10ms to 2ms, that is, 500Hz

- In order to facilitate the installation of different reducers on the same motor, the position PID and MIT PID are now based on the motor end encoder.

- The position P parameter is 100 times smaller than before, and the MIT P parameter is 100 times smaller than before.

- If you change the reduction ratio from 101 to 81/51/31 in the future, you can directly modify the reduction ratio on the parameter setting page. No other changes are required.

- The debugging software modifies the MIT page initialization P value from 9 to 0.09

📌

Note:

- For motors that are already on the arm or motors that are not convenient to restore to factory settings and recalibrate, you need to manually change the position default P parameter from 0.8 to 0.008. The MIT P parameter is changed from 9 to 0.09

- For motors that can rotate freely, just restore to factory settings and recalibrate.